Probably one of the most misunderstood two words associated with textiles and the world of Defense personal protection product development and sales. I can not count how many times I have heard the words “oh this doesn’t apply to the Berry Amendment” (well yes in fact a soft body armor vest does fall under the Berry Amendment law) or “oh yes this does meet the requirement for Berry compliance” (while I look at the manufacturing tag that says “Made in China”). So how about it – questions we are all too afraid to ask because we should know better – what exactly is and isn’t when it comes to the Berry Amendment?

First of all instead of reading marketing literature or talking to well meaning sales and business development people (myself being one), lets go to the actual DPAP (Defense Procurement and Acquisition Policy) which is a program under the Under Secretary of Defense for Acquisition and Sustainment (USD (A&S)). The Berry Amendment was originally passed by Congress in 1941 to promote the purchase of certain U.S. goods. The amendment is codified at 10 U.S.C 2533a by section 832 of Public Law 107-107. What this really means in government contracting speak is that the Berry Amendment is required – its not recommended, its not suggested, its not “maybe we should” but its a law with consequences that can involve doors and windows with bars.

For more information on violations and what the Inspector General may have found in 2016 other services is true – potentially over $200 billion in lost manufacturing manufactured overseas instead of in the United States. The Honorable Frank Kendall then Under Secretary of Defense for Acquisition, Technology and Logistics at https://www.murphy.senate.gov/download/buy-american-letter. Interesting reading but that was in 2016 and positive changes have been implemented – but back to Berry.

Here is what Berry means “the law restricts any funding appropriated or otherwise available to DoD” first and foremost this is a law which applies to the Department of Defense which means the DOJ, DHS or DOS are not required to comply with this law. They must comply with the Buy American Act (which is likely the second most misunderstood policy associated with personal protection products, uniforms and boots).

To continue “from being used to buy the following end items, components, or materials unless they are wholly of US origin:” so what this means regarding cotton

From polymer to finished product

or wool for instance is the ground that the item grows on, the people who harvest the fibers, the location where that item is processed and turned into a textile item or yarn, the location where that textile is turned into a non-woven, knit or woven material and then finished; the location and people who then cut and sew that end item into a finished good – all have to be American (which includes Puerto Rico).

The details “An article or item of food; clothing; tents, tarpaulins, or covers; cotton and other natural fiber products; woven silk or woven silk blends; spun silk yarn for cartridge cloth; synthetic fabric or coated synthetic fabric (including all textile fibers and yarns that are for use in such fabrics); canvas products, or wool (whether in the form of fiber or yarn or contained in fabrics, materials, or manufactured articles); or any item of individual equipment (Federal Supply Class 8465) manufactured from or containing such fibers, yarns, fabrics, or materials; and hand or measuring tools.” Whew that is saying a lot.

What this really means is you can’t buy boots from China and change the tags to say  “Made in America” because jail time may be included. For more examples of “can this be really true” see “chief executive officer of Wellco Enterprises, Inc. and its corporate parent Tactical Holdings Operations, Inc., sentenced 41 months in federal prison for defrauding the government” or review the investigation of Dunlap zippers incorporating a slider — the small tab and attachment that is pulled up and down to open and close a zipper — made in Asia that had very negative consequences.

“Made in America” because jail time may be included. For more examples of “can this be really true” see “chief executive officer of Wellco Enterprises, Inc. and its corporate parent Tactical Holdings Operations, Inc., sentenced 41 months in federal prison for defrauding the government” or review the investigation of Dunlap zippers incorporating a slider — the small tab and attachment that is pulled up and down to open and close a zipper — made in Asia that had very negative consequences.

So its clear that textile base materials that go into clothing and gear (including ballistics, armor and body armor) must be manufactured in the USA. But what about items that are procured for other partner countries through a FMS process? Do these still have to comply with the Berry Amendment? Yes. FMS funding and other Federal agencies’ funding is being made available to DoD and therefore falls under the Berry Amendment.  And in fact if the DoD provides funding to another agency to buy items, the Berry Amendment applies.

And in fact if the DoD provides funding to another agency to buy items, the Berry Amendment applies.

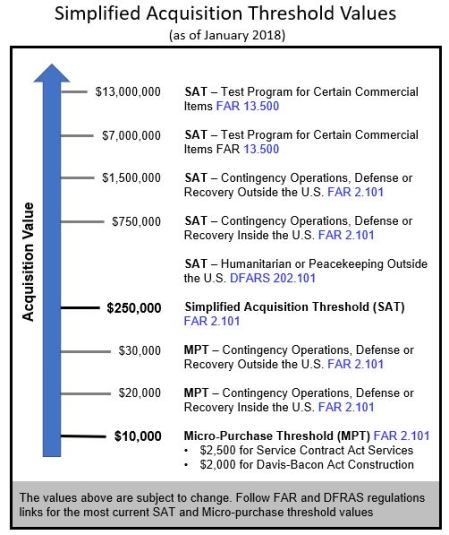

Almost last – often heard in the industry is “oh the Berry Amendment doesn’t apply because the purchase is under SAT.” So lets look at that because this is actually true. The Berry Amendment does not apply if the Government prime contract is below the SAT. In order to understand what that is we need to go to 2 CFR § 200.88 – Simplified Acquisition threshold. What SAT is the dollar amount below which organizations may make purchases using small purchase methods. Federal simplified acquisition threshold (formerly known as the federal small purchase threshold) -increased from $150,000 to $250,000. http://acqnotes.com/acqnote/careerfields/simplified-acquisition-procedures-sap So if your program or purchase is under $250,000 your policy moves from Berry Amendment to Buy American Act for compliance.

Last – “we have a DNAD so berry doesn’t apply.” Well maybe – a Domestic Non-Availability Determination (DNAD)) is a waiver to the Berry Amendment and can be granted if the Secretary concerned determines that “items grown, reprocessed, reused, or produced in the United States cannot be acquired as and when needed in a satisfactory quality and sufficient quantity at U.S. market prices.” This is not an easy piece of paper to get because the signatures are from one of these four – the Under Secretary of Defense (Acquisition, Technology and Logistics), the Secretary of the Army, the Secretary of the Navy or the Secretary of the Air Force – but good luck with that!

Converting weight from one country’s system to another, especially for those of us with military experience in Europe jumps right to converting miles to kilometers where we know its about 1 mile to 1.6 KM – or next converting the price of fuel between gallons and liters? However, when we start talking about weight and working between the United States supply chain (with a few exceptions where companies continue to quote prices in meters and not yards!) we have to convert fabric weight from ounces per square yard to ounces per square meter (lets not get into denier and dtex!).

Converting weight from one country’s system to another, especially for those of us with military experience in Europe jumps right to converting miles to kilometers where we know its about 1 mile to 1.6 KM – or next converting the price of fuel between gallons and liters? However, when we start talking about weight and working between the United States supply chain (with a few exceptions where companies continue to quote prices in meters and not yards!) we have to convert fabric weight from ounces per square yard to ounces per square meter (lets not get into denier and dtex!). Comfort translates into mission performance and staying focuses. At the crux of the issue is human performance and this really means managing the human core physiology. The amount of weight a soldier carriers is a key component to how well the

Comfort translates into mission performance and staying focuses. At the crux of the issue is human performance and this really means managing the human core physiology. The amount of weight a soldier carriers is a key component to how well the  core performs and for how long. Weight can also impact how durable a textile material remains although the textile composition may be more important. How a fabric is constructed will also impact how well that material holds up. construction also impacts how air permeates through the fabric which enables the process of moisture evaporation and cooling of the core. Again, a more air permeable fabric may have tradeoffs with a less permeable fabric – but we stray. We are talking about weight.

core performs and for how long. Weight can also impact how durable a textile material remains although the textile composition may be more important. How a fabric is constructed will also impact how well that material holds up. construction also impacts how air permeates through the fabric which enables the process of moisture evaporation and cooling of the core. Again, a more air permeable fabric may have tradeoffs with a less permeable fabric – but we stray. We are talking about weight. weight is usually a good thing and so it is with combat uniforms (to a point). So we need to know how to communicate current weight as accepted by US Military Specifications into a scale that international militaries can understand and use – enter grams per square meter.

weight is usually a good thing and so it is with combat uniforms (to a point). So we need to know how to communicate current weight as accepted by US Military Specifications into a scale that international militaries can understand and use – enter grams per square meter.